Eyelit Quality

Proactively finding and correcting production problems is critical to manufacturing efficiency and the bottom line.

Proactively finding and correcting production problems is critical to manufacturing efficiency and the bottom line. Eyelit Quality modules deliver the ability to automatically find, track and resolve quality and compliance issues from initial detection through corrective and preventive action across the enterprise. And because the system is close-looped, you know when products are perfect and in compliance, and production is working the way it should. The modules provide an integrated out-of-the-box paperless capability for configuring:

- Real-time Statistical Process Control (SPC)

- Corrective and Preventive Actions (CAPA) Management

- 21 CFR Part 11 and Other Regulatory Compliance

- Out-of-Control Action Plan (OCAP) Management

- Non-conformance (Deviation) Tracking and Disposition

- Customer Relationship Management (CRM)

- Supplier Relationship Management (SRM)

- Audit Management

- Quality Data Collection, Repository & Analysis

- RMA Management

No matter how complex the product or process, Eyelit Quality delivers remarkably flexible and easy-to-use tools for increasing quality, continuous improvement and reducing unwarranted costs. It eliminates quality-related errors as the product moves through production by continuously monitoring/searching for non-conformance, analyzing the problem, alerting the proper parties or systems, and taking action to resolve issues. The system is seamlessly integrated with Eyelit Manufacturing for providing accurate electronic device history records (eDHR). It monitors at the finest levels of detail to catch the smallest defects on the floor and help companies remedy them before they become costly problems or product recalls. Eyelit Quality enables true continuous process improvement by following issues to their root cause and electronically managing quality management processes to fix and prevent problems in the future. So enterprise quality is always under control.

Turning Quality Data into Quality Intelligence

The system performs multi-dimensional data collection at the lot, product, part or material level. It creates a central repository for all operational quality data so that no quality detail is lost. Analysis can be performed at data collection (as with real-time SPC), before, or after storing for fast issue detection or long-term trend analysis. As with all Eyelit products, eyelit Quality™ stores data in an open format that can be easily analyzed by eyelit Intelligence™ or any open database tool.

Now Quality Issues Have Nowhere to Hide

Eyelit Quality creates a paperless quality management system that extends to every corner of the business—even across facilities. With seamless integration to production and business systems, eyelit Quality™ can continuously find and take action to resolve issues before they can become quality problems no matter where they may hide.

Getting to the Root and Closing the Loop

Eyelit Quality delivers unparalleled capabilities for recording, routing, managing, and resolving the root cause of quality complaints, deviations, or non-conformance.

The system electronically manages all steps in the process:

- Generate Corrective Actions and track them through to completion

- Classify issues easily and consistently

- Associate multiple lots, products, parts, materials, manufacturing sites, vendors, or classifications to each issue

- Assign and track action items for each activity and role

- Hold and release manufacturing materials or auto-generate NCR via real-time integration with MES

- Recall product via link to MES historical data (lot numbers, serial numbers, materials, parts, or products)

- Control and verify the entire process with 21 CFR Part 11 regulation and guidance on compliant electronic records, approvals, and signatures

Get Ahead of Trends and a Handle on Audits

With Eyelit Quality you get a clear picture of trends before they become non-conformance or customer complaints. Manage internal and external audits efficiently and securely with electronic scheduling, approvals, and signatures. Document findings and actions directly to the issue record to ensure data integrity. Full integration with the QMS module means seamless corrective action follow-up.

Eyelit Management System (QMS)

Eyelit QMS, is a closed-loop, process management tool used to coordinate, track, and manage all quality and compliance issues across the enterprise. Quality assurance, manufacturing, and compliance professionals use it to increase quality, manage continuous improvement, reduce unwarranted costs, and enable regulatory compliance. The QMS module can be used as stand-alone or seamlessly integrated with other Eyelit modules, including MES and Asset Management. Eyelit QMS provides the lowest cost and most effective solution from a single vendor.

From the creation of Corrective/Preventative Action Requests (CPARs) to completion and reporting, supervising personnel and other responsible parties can manage issues through their personalized, interactive portals. Configurable HTML forms, workflows, and electronic signatures guide users through each step of the process and provide control of processes from start to finish.

Agility

Manage deviations, non-conformance, out-of-specifications, incidents, complaints, waste management, and much more.

Virtual Intelligence

Provides for a complete knowledge base of incidents and resolutions.

Integration Advantage

Provides an out-of-the-box, 100% organic/seamless MES and QMS solution.

Agility

This versatile application can be used to effectively manage deviations, non-conformance, out-of-specifications, incidents, complaints, waste management, and much more. Automatically detect incidents. Analyze issues and supporting evidence. Eliminate environmental variables that are responsible, to help your processes run smoother and cleaner.

Virtual Intelligence

As more issues become resolved the application provides for a complete knowledge base of incidents and resolutions. Full historical details on past incidents provide quality managers and process managers with the information needed to continually improve. Retrieve corresponding data collections, defect classifications, and resolutions within seconds. Link historical details to create trend pictures and common resolutions.

Integration Advantage

Eyelit is the only vendor that provides an out-of-the-box, 100% organic/seamless MES and QMS solution. Compliant with 21 CFR Part 11, Eyelit QMS’s eDHR provides detailed audit, compliance, and QMS management history as well as a full WIP tracking and genealogy history of the product (as built). The Eyelit integration advantage makes Eyelit QMS the lowest-cost solution from a single vendor.

Alert and Respond

Throughout Eyelit applications preconfigured environment sensors detect defects, non-conformances and other triggers in your operational processes. Automatically notify the correct person responsible for each type of issue raised. Escalate issues to decision-makers, send out corrective actions, tap into events outside the QMS application (ERP, MES, PLM, LIMS, etc.), and obtain a complete enterprise management solution.

Data Collection and Reporting

Configure personalized process management screens with HTLM forms. Print or export audit reports and incident tracking information directly from clients. Create custom reports using built-in filtering and report-structuring tools.

Eyelit Statistical Process Control (SPC)

Instant detection and notification of production problems

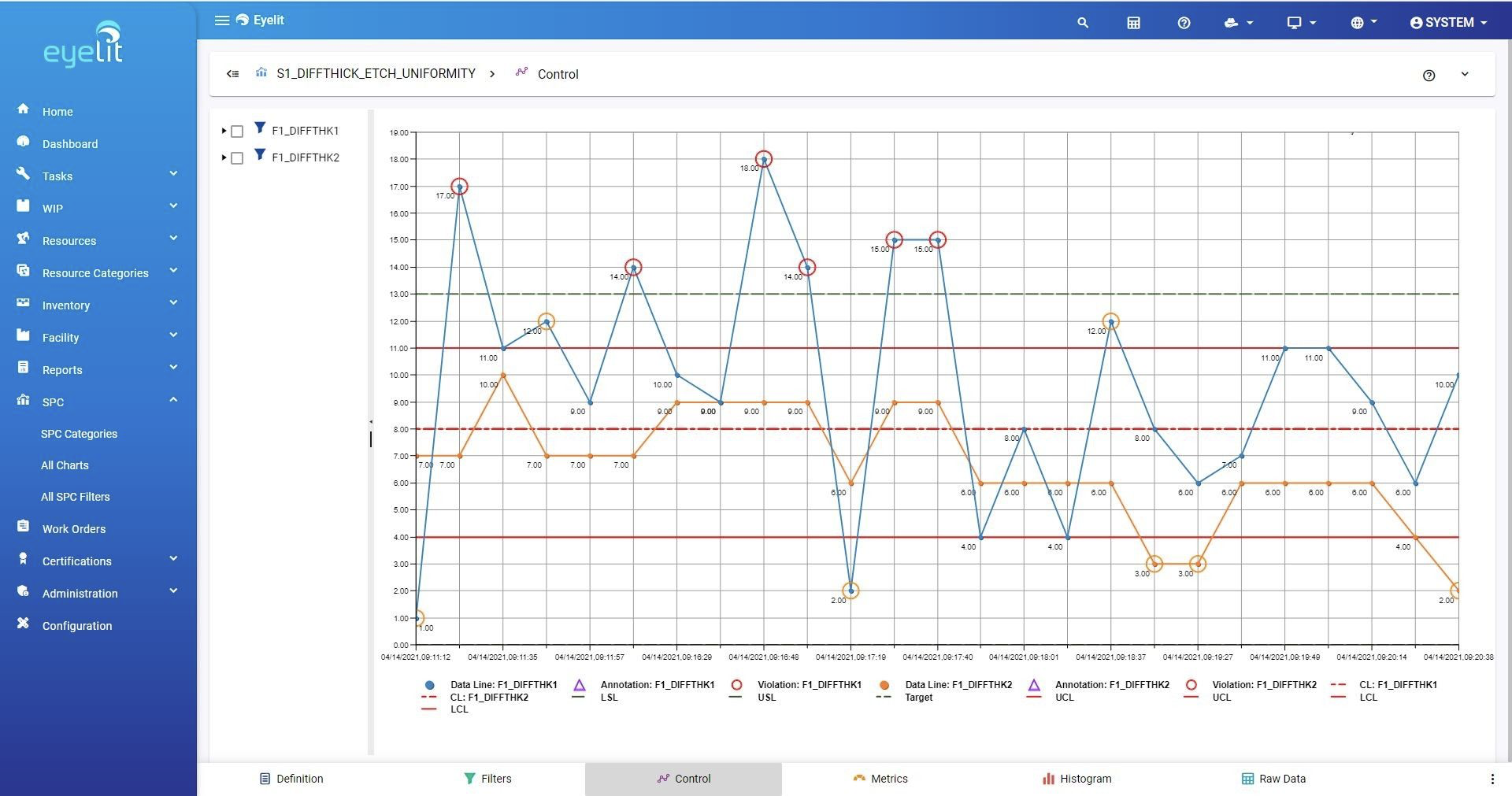

The Eyelit SPC module provides statistical process control capabilities using data collected through data collection operations configured in Eyelit MES and Eyelit Asset Management. It provides real-time controls, charts, and reports. It may also be used as a standalone application or integrated into external systems using Eyelit FactoryConnect.

Eyelit SPC™ determines when the variation in a process has exceeded “normal” behavior and is considered “out of control”. SPC calculations are applied to raw or summarized data, and the results are then graphed for easy viewing.

Once identified, out-of-control processes can command the appropriate level of management’s time and attention, and strategies can be devised to address them. For example, WIP or equipment may automatically be placed on hold and an engineer paged if any anomaly is detected.

Charts are easily configured by end-users:

- Define manual limits

- Include larger groups and samples

- Show or hide exclusions

- Include data from multiple operations

- Select which Western Electric, Nelson, and Rolling T rules to apply

Variable Charts

Monitor numerically ‘measurable’ features, such as thickness, height, length, etc.

- Chart types include XR, XS, Median-R, Median-S, XmR, EWMA

Attributes Charts

Monitor ‘countable’ features, such as the number of defects

- Chart types include C,U,P,nP

Histograms

Generate Histograms; data distribution charts that show the frequency of measurement values that do not take into consideration the excluded points.

Trend Charts

Generate Trend Charts; data points charted in a time series.

SPC Reports

Reports are available with summaries of analysis results and with summaries of OOC conditions across multiple areas of the factory.

Review and export chart data

For each data point, you will see the data point’s timestamp and measurement value. Both the process tool and measurement tool are available. There is another view with statistics for the chart, such as calculations, limits, etc. SPC chart data may easily be exported for access with any 3rd party Data Analysis software.

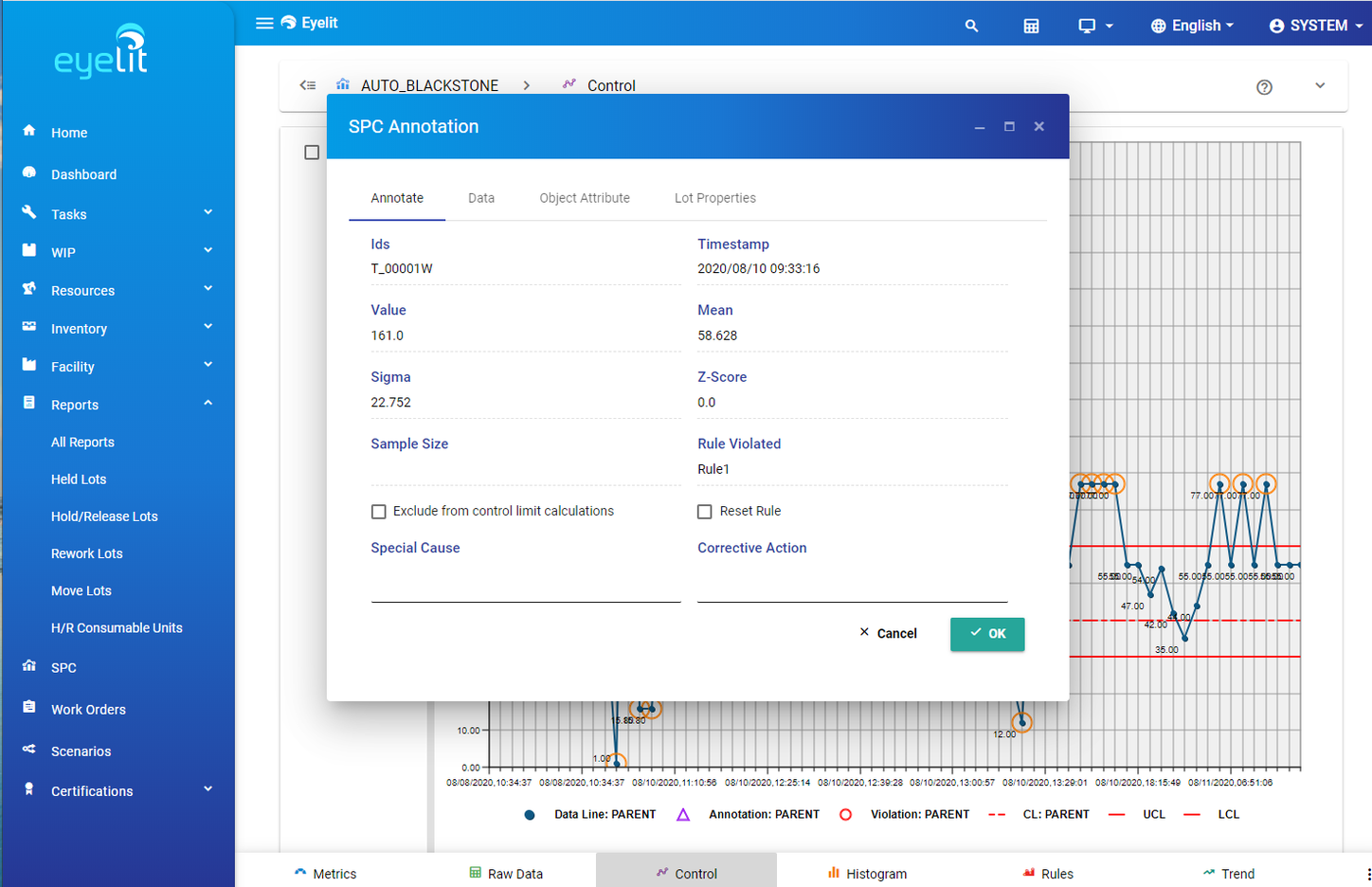

Chart annotation

Points may be annotated and/or excluded from Control or Run charts. Clicking on a point in the chart brings up the editing screen. One may also easily identify if a chart has any offending points (OOC, OOS, RULES) which are not annotated.

SPC Chart filters

Filters may be defined on charts to selectively plot data. For example, it may be desired to filter by a Product Id, a data collection operation, data collection Variables, or a specific process Tool.