EYELIT AUTOMATION/INTEGRATION

Eyelit’s advanced Automation and Integration modules leverage an exceptional no/low code capability that has enabled a wide spectrum of enterprise integration and automation capabilities for over 20 years. Eyelit’s integration platform supports Industry 4.0 initiatives and connectivity throughout the entire scope of vertical and horizontal value chains. Eyelit has uniquely delivered integration with various legacy MES solutions such as Camstar, FactoryWorks, PROMIS, WorkStream along with numerous custom MES solutions.

The Eyelit Automation/Integration and Enterprise modules support the wide spectrum of integration and automation capabilities for Industry 4.0 initiatives and connectivity throughout the entire scope of vertical and horizontal value chains of data. From shop floor equipment to consumer smart devices, these modules help to manage, make sense of, and optimize the use of, large volumes of data throughout factory automation, Smart Manufacturing, the Internet of Things (Iot), Internet of Systems, and global virtual enterprises.

Connecting the easy way

To keep up with the speed of today’s demand-driven manufacturing world, information needs to be shared flawlessly and fast.

Eyelit Automation/Integration easily connects any application, device, or tool regardless of location or operating platform Eyelit Automation/Integration provides completely flexible, proven, easy-to-use connectivity between manufacturing and all external services, such as:

- Enterprise Systems

- Factory Applications

- Process and Metrology Equipment/Tools

- Custom Applications

- Data Warehouses

- Devices

- Outsource and Supply Partners’ Systems

This means manufacturing-related operations are constantly communicating with each other in real-time to create an organization capable of instantly reacting to changing business needs. For instance, when inventory reaches a specified low level, Eyelit Automation/Integration keeps MES transacting with your ERP system to generate a requisition for more materials automatically. Or, as high volumes of product are manufactured, connections between MES and QMS/CAPA ensure that issues get flagged and quality managers are alerted the instant a problem is detected.

Eyelit’s advanced technology platform, on which all Eyelit software is built, creates a method of integration that allows virtually anything to connect to the system quickly and easily, greatly reducing the cost and time of integration. It uses a service-oriented architecture for integrating heterogeneous business and manufacturing applications/processes.

No code/Low code Scenario Manager

With its Scenario Manager’s configurable, embedded use case business logic you can easily customize and personalize your own event handlers to deal with your unique business processes—with or without coding. Plug-in application adapters tie manufacturing systems to the major business applications in just a few hours. Eyelit provides the most robust, reliable, and easy-to-implement manufacturing connectivity framework available. The unique advanced technology makes connecting manufacturing to the rest of the enterprise quick, simple, and completely reliable.

Connect to Any System, Anywhere

Eliminate islands of information and seamlessly bridge diverse platforms using the most versatile, simple-to-use technology that makes connection to any system or platform—local or global—not only possible, but easy.

Fail-safe Monitoring

Constantly monitor the health of the connections. Built-in configurable corrections and automatic fail-over to keep the system optimized 24×7.

The Fastest, Easiest Integration System Available

Application adapters for major business systems and Eyelit’s easy-to-use technology connectors are up and running in a few hours.

Never Miss Another Issue

Eyelit’s unique Event Manager continuously listens for configured events and monitors all connected operations. It allows action on any incident/event, even if it happens outside the system so that you know issues will be caught before they turn into profit-eating problems.

Proven Reliability

Eyelit Automation/Integration has been tested under the highest throughputs and used in the most demanding 24×7 manufacturing environments with failover servers so that you know you’ll get the mission critical reliability your business demands.

Eyelit FactoryConnect (FC) and EnterpriseConnect

Eyelit FactoryConnect™ is a configurable integration hub used to centralize connectivity and coordinate information flow between heterogeneous applications throughout the factory. It can operate as an Eyelit Integration™ module or as an independent application integrated with other MES systems in cases where Eyelit MES™ is not implemented.

For production-intensive automation applications, FactoryConnect™ delivers critical information rapidly between systems, tools, transport systems, and users. Built on Eyelit’s platform-independent, Java-based application framework and Scenario Manager, it provides the capabilities for listening to and responding to events from any application in real-time.

User-defined information handlers process events and requests (in a synchronous or asynchronous manner) and may trigger other handlers, respond to the requester, store to a database, send notifications, requisition another application, etc. The Eyelit EnterpriseConnect™ module provides similar capabilities, on the same architecture, for integration between factory applications and higher-level business systems such as ERP, PLM, Schedulers, etc.

Deploys and managing robust equipment control in the most cost-efficient manner.

Provides advanced technology for Industry 4.0 initiatives and smart factories.

Supports full, semi, and offline automation modes enabling operators to interact with and monitor equipment.

Connects directly to factory equipment and/or smart devices faster.

Leverages Advantages of Eyelit’s Scenario Manager

- Condition-based automation

- Requires no downtime to implement or modify

- Enables changes through configuration without programming

- Adapts quickly to add/remove/change automation behavior

- Provides easy troubleshooting as logic is easily visible in error logs

Flexible Extensibility with Security

Eyelit FactoryConnect™ was designed for rapid implementation and flexible configuration for secure agility and extensibility. Some key features are:

- Integrates seamlessly with legacy and new systems

- Supports clustering and load balancing with linear scaling, supporting heavy transaction loads and providing failover capabilities

- Maintains a persistent data cache to protect the integrity of data

- Supports custom business agents (with logic) for modeling automation processes spanning factory systems

- Enables platform independence, supporting a wide array of hardware and software platforms

Open Connectivity Services

Virtually any application can be integrated with a wide variety of connectivity services for sending and receiving messages in an open systems heterogeneous environment. Services supported include:

- Web Services

- Simple XML over Sockets

- Message bus

- SMTP Email

- FTP service

- Flat File

- JDBC for database connections

- RMI for distributed Java applications

Eyelit EquipmentConnect (EC)

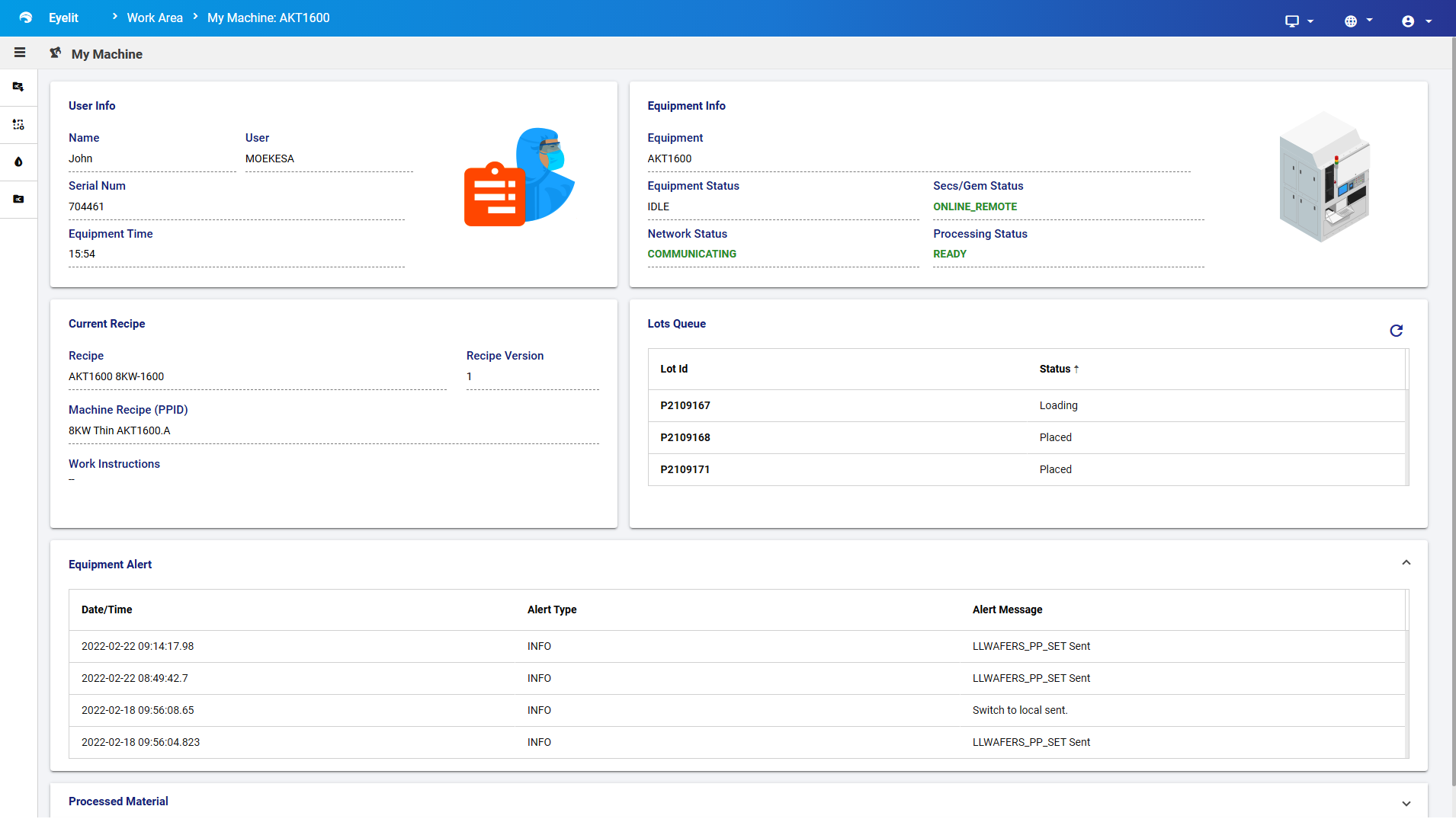

Eyelit’s EquipmentConnect

Eyelit’s EquipmentConnect module is a configurable equipment integration application for deploying and managing robust equipment control in the most cost-efficient manner. It supports full, semi, and offline automation modes enabling operators to interact with and monitor equipment through the configurable Eyelit MES Operator GUI. A custom GUI is not required for automated tools; EquipmentConnect simply handles the equipment control and operational scenarios behind the scenes. It has also been integrated with other MES systems and custom GUIs through Eyelit’s FactoryConnect module.

Scenario Modeler

It leverages a standard set of operations to select from, such as Verify Recipe, Place Pod, Select Recipe, Lock Pod, etc…and is reusable across equipment types. The extendable architecture and configurable visual Scenario Modeler can also be utilized for implementing unique tool operations (logic and message/alarm handling workflows). It operates seamlessly on the same architecture executing transactions through FactoryConnect. Standard interface adaptors support SECS/GEM, XML, OPC, File, RFID, and Database connectivity. Equipment connections can be easily initiated or re-started on the fly, in a graphical drag and drop manner.

Industry 4.0, the Smart Factory, M2M and the Internet of Things (IoT)

EquipmentConnect provides advanced technology for Industry 4.0 initiatives and smart factories. It facilitates machine-to-machine communication (M2M) and the internet of things (IoT) helping companies increase automation and communication. EquipmentConnect enables Eyelit’s customers to connect directly to factory equipment and/or smart devices faster, and at dramatically lower costs. EquipmentConnect. It simplifies automation and eliminates the need for third-party software, such as expensive message buses. Built on Eyelit’s proven architecture and history of integration, it can completely replace traditional cell or area controller software.

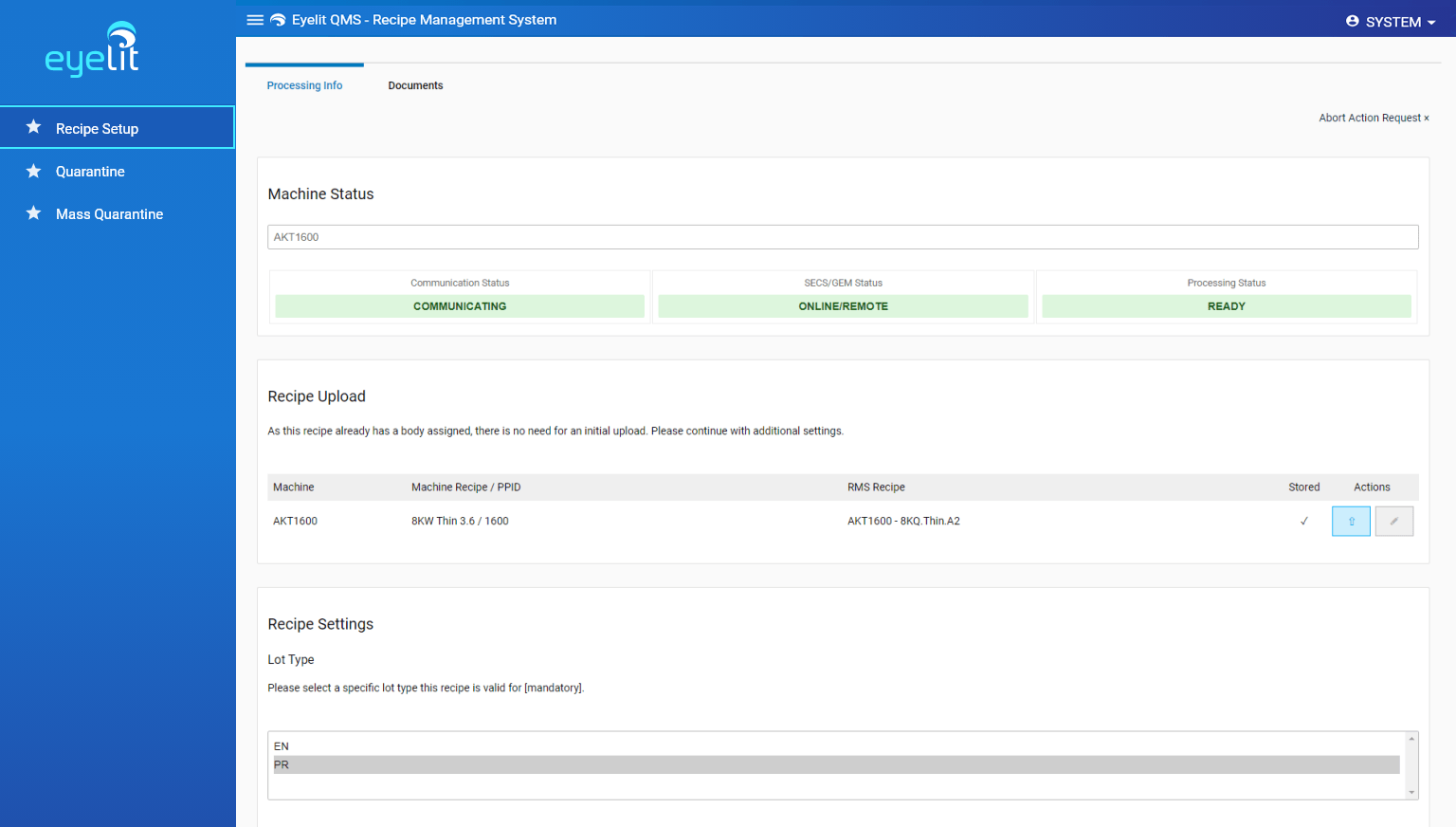

Eyelit Recipe Management (RMS)

Precision Automation

Automation has become critical for high-tech manufacturers due to the complexity of tight specifications, a high mix of products, fast cycle times, and a need to maximize overall equipment effectiveness (OEE). Eyelit RMS helps enforce precision automation that prevents mistakes, increases throughput and yield, and adjusts processing to prolong the time between required maintenance activities. Eyelit RMS may be used as an Eyelit module or as a standalone system integrated into other systems through FactoryConnect.

Feed Forward, Feed Back

The RMS module extends the capabilities of Eyelit MES to enforce and coordinate feed-forward and feed-back adjustments to the detailed settings of equipment recipes at a processing step. The version-controlled instructions in the Manufacturing Execution System (MES) store the process program identifier (PPID) and system variable identifiers (SVIDs) within them, at each step of a process with automated equipment.

The PPIDs, SVIDs, child equipment, and chambers of cluster tools can be managed as variables with override capability at the process, product, lot, and unit (e.g., wafer) levels. The value of each variable is downloaded to each equipment controller when automating through Eyelit FactoryConnect™ to enforce proper processing of the material, and values of parameters collected may be passed back to the MES. Sub-Recipes enable a reusable collection of recipe parameters that can be applied to one or more Recipe Templates. All parameters associated with a Sub-Recipe are automatically inherited by the Recipe Template(s) to which the Sub Recipe is associated. Sub Recipes can also be nested, allowing a parent-child relationship.

Advanced Process Control (APC) Enforcement

FactoryConnect supports RMS integration with APC controllers and their sophisticated algorithms for Run-To-Run (R2R) control adjustments of SVID variables as lots and batches are processed. It is also capable of exchanging SVID variables with APC that has in-situ controls for unit-to-unit (e.g., wafer-to-wafer) adjustments of SVID variables as the material moves between chambers within-cluster tools.

Eyelit Automated Data Services (ADS)

Simple Data Loading

The Eyelit Automated Data Services module provides end-users with easy data import and MES transaction execution capabilities through intuitive script commands. This provides a very flexible, even ad-hoc, alternative to entering transactions through the Graphical User Interface.

Automated Data Services is the simple way for users to utilize external data sources. Users just provide a database file or flat file of data (e.g., an Excel spreadsheet or .csv file) to use with a scripted transaction, or sequence of transactions, and then map them for execution. The mapping is straightforward; just match the names of columns in the spreadsheet to the Eyelit MES objects in the scripted transaction. The scripts are reusable at any time with other sets of data.

Lowest Cost Integration

ADS has been used by customers for a wide variety of very fast and low-cost integration purposes including populating the Eyelit database when implementing the system, migrating from legacy systems, tool integration for data collection, and triggering lot starts in Eyelit from external systems.